An Australian study outlines a technical framework to repurpose used solar modules and cut environmental waste.

Australia’s rapid uptake of rooftop solar has helped decarbonize the grid, but it’s also setting the stage for a new environmental challenge. An estimated 280,000 tonnes of end-of-life photovoltaic (PV) panels will accumulate in Australia by the end of 2025, with most still heading to landfill due to missing infrastructure for reuse.

To address this, University of South Australia researchers have proposed a national framework for testing, certifying, and tracking used PV panels, which combines engineering protocols with digital traceability to enable secondary markets and extend solar asset lifetimes. Their work is published in Sustainability.

Discarded PV panels. Image used courtesy of Adobe Stock

Why Good PV Panels Go To Waste

Standard silicon PV panels are designed to last 25-30 years; however, many are removed prematurely, often due to system upgrades, minor frame damage, or inverter replacements. Despite retaining 80-90% of the original output, these panels are rarely reused. Instead, used panels can end up in the waste stream.

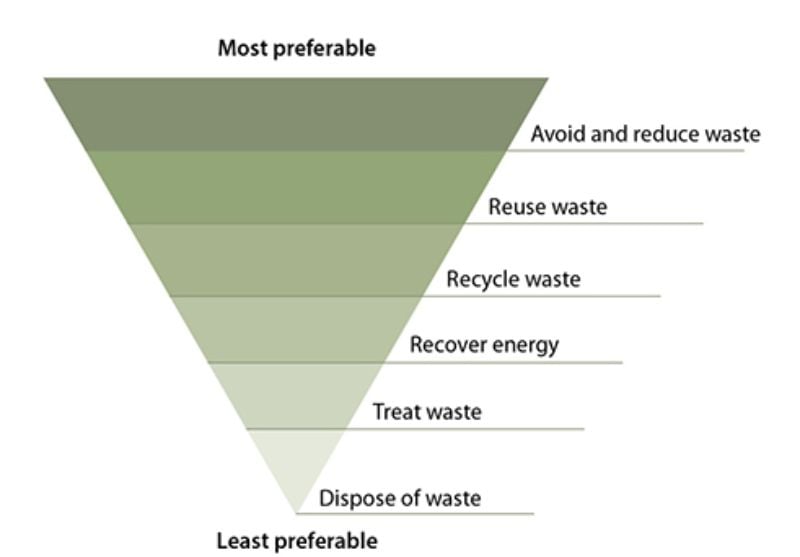

The PV hierarchy, according to the New South Wales Environmental Protection Agency. Image used courtesy of Chhillar et al.

The study recognizes a viable solution: creating a circular economy that prioritizes reusing the old panels. However, no standard testing infrastructure or certification process exists to verify whether a used panel is safe, functional, or worth reinstalling.

Engineering PV Panel Reuse

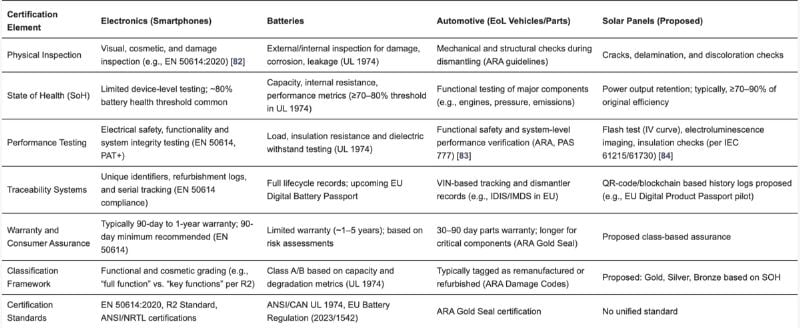

The study highlights the need for a national reuse certification scheme, informed by existing circular economy practices in sectors like electronics and automotive parts. Without a uniform approach to performance testing, liability, and traceability, second-life solar remains an informal and underutilized market.

The authors propose three technical pillars:

- Standardized Testing Protocols: These would include insulation resistance testing, electroluminescence imaging, power output measurements, and physical inspection. The goal is to quantify panel degradation, detect internal damage, and verify electrical safety.

- Grading and Certification: A “gold-silver-bronze” or star-rating system would allow consumers to assess used panels based on remaining efficiency and expected lifespan.

- Digital Traceability: The study explores digital tools to track panel history and condition throughout its lifecycle, removing uncertainty for resellers, buyers, and regulators.

The researchers considered the criteria applied to reusing other electronics. Image used courtesy of Chhillar et al. (click to enlarge)

That traceability is central to the proposed solution. The researchers envision a system that assigns each panel a digital ID, which could be as simple as a QR code or as advanced as a blockchain record, documenting manufacturing origin, installation, testing results, and refurbishments over time.

Other industries have already implemented such reuse infrastructure. The authors mentioned established practices in electronics, batteries, and mobile phones as examples of how structured refurbishment, grading, and resale models can work.

The PV Reuse Policy Barrier

While the technical challenges are solvable, the study points to policy inertia as the larger problem. Currently, no national standards for PV reuse or refurbishment exist, and there are no incentives for second-hand systems. Further, installers who handle reused panels have no liability protections.

The researchers concluded that a well-designed certification system could reduce environmental waste and open up new market opportunities for second-life panels, but policymakers need to introduce standards and regulations.