A University of Sydney team has created a 23.3%-efficient, 16 cm2 tandem solar cell with world-first stability metrics.

In a leap forward for next-generation photovoltaics, University of Sydney researchers have developed the world’s most efficient and largest triple-junction perovskite-perovskite-silicon tandem solar cell. It reportedly achieves 23.3% steady-state efficiency across a 16 cm2 active area. Even more impressively, a smaller 1 cm2 version clocked 27.06% and passed industry-standard durability tests, marking a global first for this solar architecture.

The research demonstrates that triple-junction cells, long limited by scaling and stability barriers, can now achieve both size and performance without compromise.

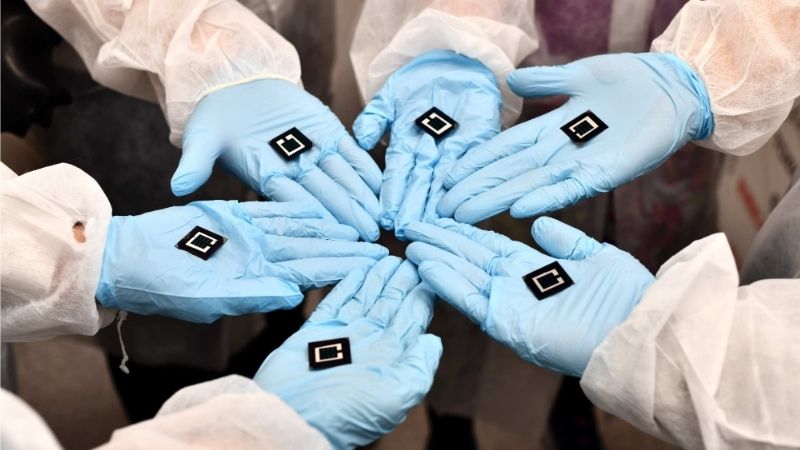

The 1 cm perovskite solar cells. Image used courtesy of University of Sydney

Perovskites at Scale

Perovskite tandem cells have been gaining traction due to their potential to surpass the theoretical efficiency limits of silicon-only PV. But real-world deployment has been hamstrung by two technical gaps: durability and scalability.

This latest effort directly addresses both. The 1 cm2 device not only achieved 27.06% certified power conversion efficiency, but also survived the IEC 61215 Thermal Cycling test, enduring 200 full swings between -40°C and +85°C while retaining 95% of its performance after 407 hours of continuous operation under light.

The larger 16 cm2 cell, certified at 23.3% steady-state efficiency, is the biggest of its kind to break the 20% threshold, making it one of the most promising contenders for large-area tandem solar modules.

Materials Science Meets Interface Engineering

To create the high-efficiency triple-junction device, the team combined two wide- and mid-bandgap perovskite layers with a bottom silicon junction. Each layer was tuned to capture a distinct portion of the solar spectrum. But performance gains came from more than just stacking.

![]()

PV performance and stability of the triple-junction-perovskite-perovskite-silicon tandem. Image used courtesy of Zheng et al.

Researchers replaced the volatile methylammonium component in traditional perovskites with rubidium, improving structural stability. The commonly used (and unstable) lithium fluoride interface layer was also replaced with piperazinium dichloride, enhancing defect passivation and carrier transport.

On the interface level, the team used gold nanoparticles rather than a continuous gold film to connect the top and middle perovskite layers. Transmission electron microscopy confirmed the nanoscale structure, and optimized particle coverage was key to improving both optical transmission and electrical conductivity. As a result, the cell achieved a high open-circuit voltage of 3.16 V and a fill factor of 83.6% on the small device, with similar stability metrics pushed toward larger formats.

The Largest Triple-Junction Perovskite Demonstrated

The triple-junction configuration follows a straightforward principle of stacking three photovoltaic junctions with descending band gaps to absorb more sun energy. However, building a stack that works in the lab is different from one that works in real-world settings, especially over time and temperature.

That’s why this development is being closely watched. Until now, perovskite-perovskite-silicon cells have largely been experimental. Demonstrating high efficiency at 16 cm2 with verified durability opens the door to commercial-scale modules, especially for space-constrained or high-performance applications.

Researcher Anita Ho-Baillie in the laboratory. Image used courtesy of University of Sydney

For engineers designing the next generation of solar infrastructure, this research offers a credible path toward >25% efficiency panels that don’t rely on exotic materials or impractical manufacturing techniques. Perovskite-silicon tandems can be fabricated using low-temperature, solution-based processes, ideal for reducing capital costs and increasing throughput in PV manufacturing lines.

More importantly, the verified stability over hundreds of hours under thermal cycling and continuous illumination makes this cell format a realistic option for utility-scale, rooftop, or mobile solar systems.